|

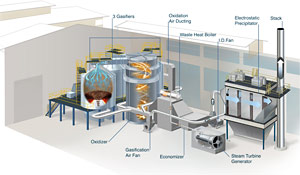

Steam – High Pressure Configuration of 20 MWth/1.4 MWe CHP plant

For customers who need high pressure super heated steam for conventional steam turbine power generation or for any other high pressure steam requirements (such as District Energy Plants, Industrial Process Plants and Independent Power Producers), Nexterra can provide economical steam systems capable of over 650 psig of superheated steam. The desired balance between power and heat will dictate the selection of the appropriate steam turbine technology (back pressure, extracting, or condensing).

Contact us to see if your project is a suitable candidate for our high pressure (Power/CHP) steam system.

|